使用与详细资料/Purpose and introduction

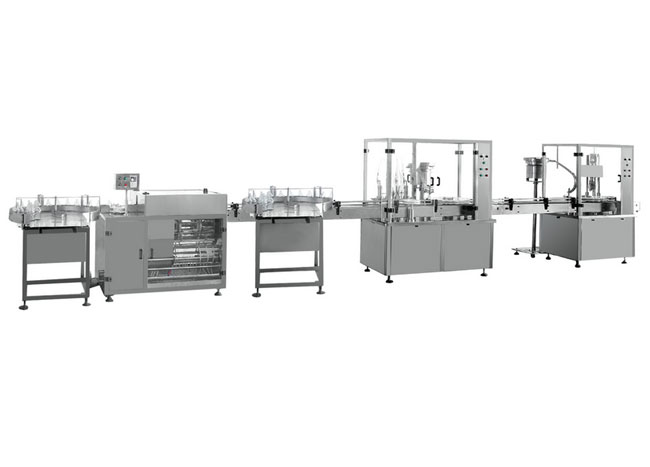

该生产销售线由理瓶机(上瓶台)、超音波波洗瓶机,灌装的设备(旋盖)加塞机,轧盖机,标贴机等的设备组建On the production line by unscramble bottle machine (bottle), ultrasonic bottle washing machine, filling (screw cap) stoppering machine, rolling machine, labeling machine and other equipment

优点/characteristic:

该产生线非常比较时候于 30-500ml系列表新产品的灌装设备加塞封口处,修改其他规格型号压铸模具后,既非常比较时候于塑胶片瓶,也非常比较时候于玻璃窗瓶。具备有习惯区间诸多,懂得调整便的显著特点。整线产生效果;适塑料瓶子多少形状图片,物块107硅橡胶粘度而定。The product line is suitable for 30-500 ml series products filling barging sealing, change some specifications after the mould, is suitable for plastic bottle, also suitable for glass bottle. Have to adapt to a wide range, convenient adjustment. The whole line production capacity; Optimum size bottle shapes, object on the viscosity.能力参数指标/technical parameters:

生产能力production capacity(pcs/h) | 80-120(8针灌装、6头轧盖 |

洗瓶无尘室度Washing bottle cleanliness(%) | > 99 |

装量测量误差The load error(%) | 0-2 |

上塞合格品率Plug on the percent of pass(%) | > 98 |

轧盖通过率Rolling cover percent of pass(%) | > 98 |

功率power(kw) | 11 |

外形尺寸boundary dimension(LxWxH) (mm) | 9.740 × 1,470 × 1,785 |

-

18217001818

18217001818

-

shnalong@aliyun.com

shnalong@aliyun.com

-

东莞纳庆物理机器有限的公司的

东莞纳庆物理机器有限的公司的

中文

中文  English

English